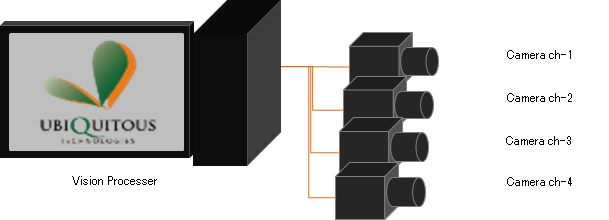

For Ubiquitous Automation,

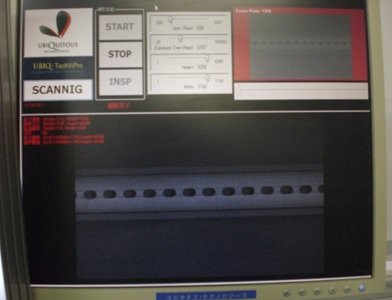

Image Processing controller Ubiquitous Technologies Vision Processer

By using our one-stop service, we could provide the best optimal system that you desire.

| Area Camera | 0.3~5 Mega Pixels |

|---|---|

| Line Sensor Camera | 2K~8Kbit ✕ Line numbers |

PC: PC/AT-Compatible Machine(DOS/V)

CPU: Pentium Processor

Memory: 256MB and above

HDD: 1.6GB and more free space

Display: XGA(1024×768)above

OS: Microsoft Windows Vista/Server 2008/7/8/x64、Linux x86/x86_64,MAC OS X 10.8/9/10

Microsoft Visual Basic 2005 above, .NET、Visual C++, .NET、Visual C#

※Windows XP not covered

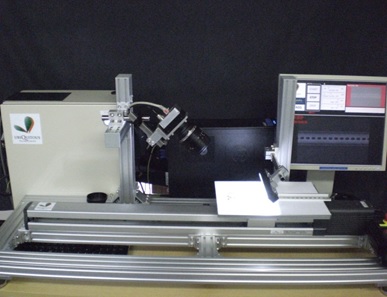

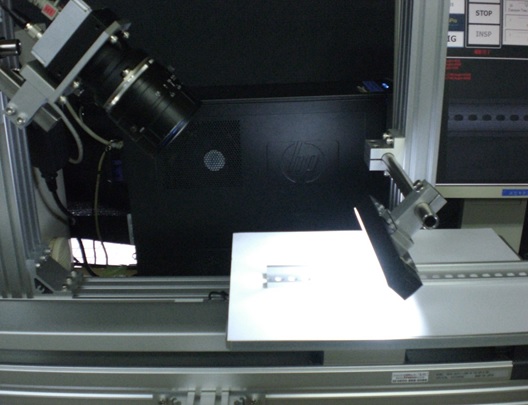

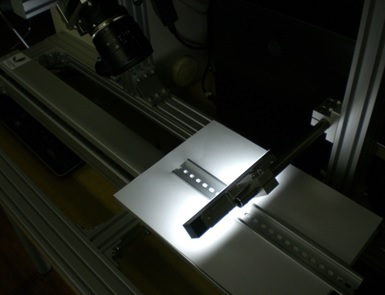

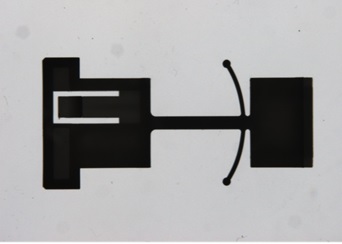

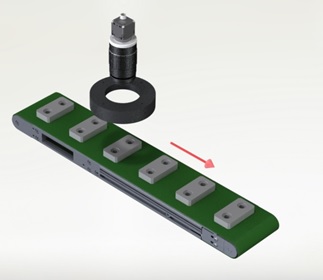

Image experimental unit with line sensor camera installed in general purpose type stage.

Can also be used as automatic inspection system and for visual inspection.

Separately, please also consult us for design selling of inspection applications.