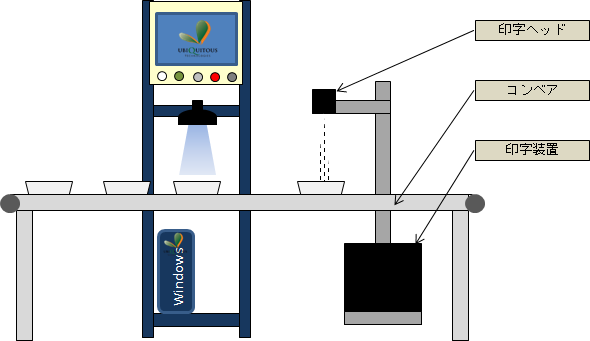

Frame and Control for image processing are One Stop Design from UBIQ

UBIQ will adjust to the customization you desire such as connecting to conveyor, electrical specification, lamp lighting controller, your specified controller, cover coloring, and water even prevention cover attachment.

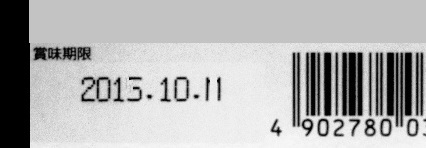

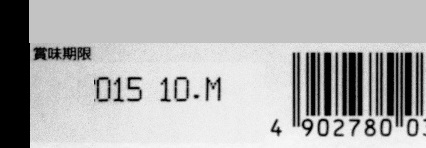

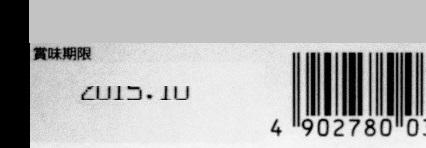

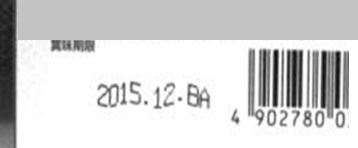

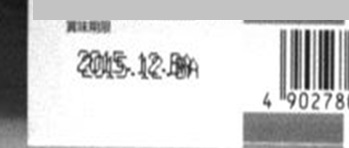

Printing Miss, Printing Omission, Missing text, blurry text, Detection of Printing misregistration

independent type equipment structure as standard for easy attachment of existing conveyor and transport mechanism

(Ex.) Camera View Angle : 140mm

Reusable shipping

carton

Paper

container

Paper

pack

Transparent resin

container

Bag

Package

UBIQ will provide machinery that will meet your needs by designing the it by ourselves. If there are any problems such as unclear printing surface samples, complex reflections, hard time with attaching the inspection camera, please do not hesitate to contact us.

Inspects the vinyl, hair, paper and other contaminants in a food packages

Controller : Windows8.1 DOS/V-PC

Camera : 1.3M Pixels USB-IF × 4 devices

Contaminant will be detected by elliminating unnecessary reflection parts using image processing technology

Portal type